Table of contents

Table of contents- Service Level and Its Impact on Inventory Management

- What is Service Level?

- What Criteria Help Establish the Level of Service in our Company?

- What Metrics Can We Use to Measure the Level of Service?

- What Impact Does Service Level Have on Inventory?

- What Is the Relation Between Service Level and Safety Stock?

- What Is the Formula for Calculating Safety Stock?

- How Does the Service Level Impact the Assortment?

- How to Optimise Service Levels

- Service Levels FAQs

Stockouts and overstocks are two sides of the same coin. Importantly, though, both are very damaging to a company’s bottom line.

On the one hand, breakages result in lost sales and revenue that your company will miss or, at the very least, realise at a later date. On the other hand, overstocks become obsolete in your inventory and therefore devalue your stock.

To achieve a balance that allows for optimum stock, without breakages or excesses, it is important to optimise. This can be achieved in different ways, but the level of service is a fundamental parameter.

What is Service Level?

If we focus on the theory, the supply chain management approach to service level refers to the probability of not reaching a stockout situation and, therefore, of being able to serve the customer. In other words, if our service level is 95%, it means that we will be able to satisfy the demand of 95 out of 100 customers.

What Criteria Help Establish the Level of Service in our Company?

The level of service we offer our customers is the result of our company’s strategy. Providing good levels of service costs money. We can have a strategy of never failing our customers, which implies higher costs, or a strategy in which the cost is the basis, implying we do not care so much about not serving an order to keep our costs under control.

What Metrics Can We Use to Measure the Level of Service?

Service level can basically be measured in two ways. The first is to measure the number of times a customer asks for something and we are not able to meet their demand. And the second is to measure availability, i.e., how many references I want to have in stock and my stock is zero.

And why these two different ways? Well, because, for example, in a distribution business where we receive orders from our customers, we can measure the percentage of them that we cannot serve because we do not have stock. However, in a business such as a shop open to the public, we do not have orders from the customer, but the customer takes what they see on the shelves. As such, we do not know whether or not they would have taken an item that is not in stock.

In the first case, we would measure the stock level based on stockouts (I don’t have and I am asked for) and in the second case we would measure it as availability (I don’t have something I would like to have).

What Impact Does Service Level Have on Inventory?

And what effect does the service level have on inventory management? Well, one of the most direct impacts is on safety stock. And this is because, if we aim to have a 99% service level, it will be necessary to invest a lot of resources in the availability of items. If these references have high deviations in demand or supply (supplier reliability), it’ll result in a very large safety stock that will be difficult for the business to afford.

What Is the Relation Between Service Level and Safety Stock?

Understanding the relationship between safety stock and service level is key for all companies that want to increase the profitability of their business. Any company that wants to guarantee sales while minimising risk must have the right products, at the right time, in the right quantity, and in the right place.

Theoretically, it is not difficult to buy the units needed to cover the cycle that makes up the lead time and the frequency of purchase. But in practice, we have two major uncertainties: supplier reliability and demand variability. If we do not consider these variables correctly in our supply calculation, stockouts or overstocks are inevitable. Safety stock is one of the resources that allow us to prevent stockouts.

What Is the Formula for Calculating Safety Stock?

There are different formulas for calculating safety stock depending on the target service level. The formula below is a simplified version recognised in inventory management theory:

The Z-factor in the above formula is drawn from a normal distribution table with the desired service. The level of service conditions the Z-factor.

Sourcing teams can use multiple formulas to calculate safety stock in a spreadsheet. However, doing these manual calculations is inefficient, as there is inventory optimisation software that not only calculates this percentage in seconds, but also uses statistical models with different variables to reach conclusions according to specific objectives.

How Does the Service Level Impact the Assortment?

Differentiation by service level is a fundamental process when we are seeking to optimise supply. Deciding what level of service we want to provide for each of our references, in each of the stock points to be managed, is key.

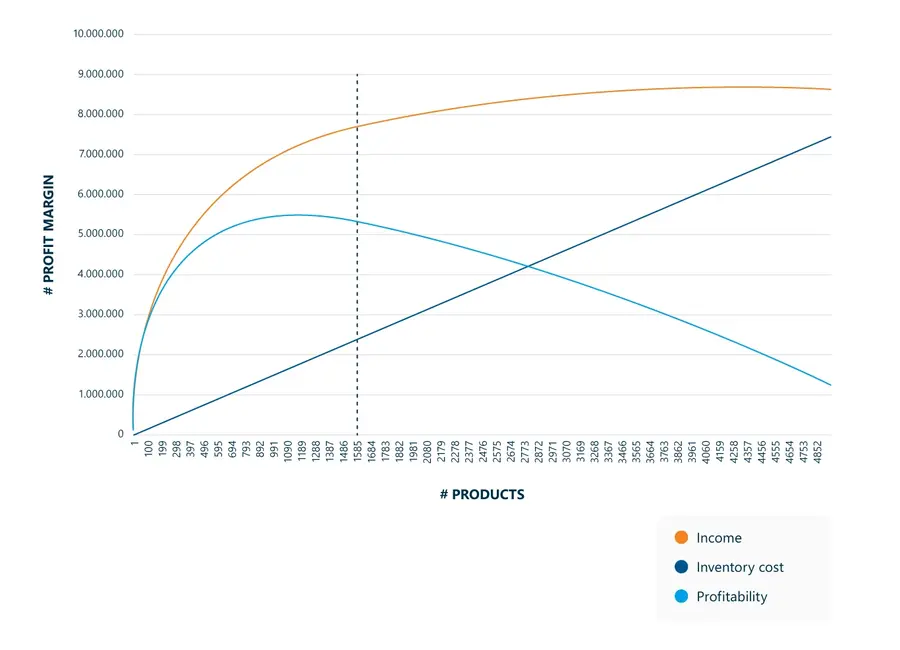

When we present differentiation by service level, I always like to start by presenting the following figure. On the horizontal axis is the width of the assortment, i.e., how extensive is our product portfolio. And on the vertical axis, for simplicity’s sake, we have the money it brings us.

The green line indicates that few references bring in a lot of money, and then the curve gradually flattens out until it reaches the point where, no matter how much I increase the assortment, it will not bring me any more income.

In red is the cost of managing this assortment. As we increase the assortment, the costs of owning and managing more references increase.

And in the black, we have the actual profitability of our assortment. There comes a point at which our assortment is no longer profitable. Let’s not panic, though; this does not imply that all stock should be removed from the dotted line. We all know that in order to get our customers to buy the super A products, we often have to show them a wide range of products. So, what is the importance of this graph? Well, it relates to the target service level that we will give to our references.

A super A reference will not have the same level of target service as a long tail reference. As we saw earlier, this has a very big impact on the safety stock that we will have of each of the references and, therefore, on the working capital that we will have invested in each product.

There are different ways to approach this policy, all of which are equally valid. The first thing we need to decide is the criteria that will determine the level of service we apply to each group of references.

The first decision, then, is to determine whether these criteria for marking the product segmentation are going to be one or more than one. My recommendation is that there should be no more than two. If you decide that you want to start by applying only one segmentation criterion, because your company is introducing the concept of service level or you do not have the necessary tools to introduce more criteria in the calculations, I recommend that this is the ABC classification by revenue or by margins provided by each reference.

How to Optimise Service Levels

The optimisation of service levels is not straightforward and is usually industry-specific. The analysis is quite complex and the challenge lies in the time period under consideration.

It is well known that customer sensitivity to out-of-stocks and lead times varies between products, so the optimal service level must therefore be specific to each product. However, approximations are generally used to reduce the complexity of making a calculation for each SKU if your company has hundreds.

Normally, the higher the level of service, the higher the customer satisfaction.

However, there are environments where the customer knows they cannot count on a high level of service. If we think of an outlet shop, the customer is aware that they will not be able to find all sizes of all references. This is because the reduced price they are paying compensates for the poor level of service.

However, if I am shopping in a luxury shop and I am paying a high price for a product, I expect it to be available in all sizes in all colours of whatever model I choose. And if the store doesn’t have it at the time, the customer’s expectation is that it will be available very soon after.

Similarly, when the customer goes to buy headphones, without having a specific model or brand in mind, they expect to leave the electronics shop with the product they were looking for.

However, when it comes to highly desirable new product launches – we see this every time a new iPhone model is released – or specific items with sustained high demand over time – as was the case with the PlayStation 5 – the level of service drops considerably, yet the customer is much more understanding.

Service Levels FAQs

Service Levels FAQs

Service level in the supply chain domain refers to the ability of a company to meet the needs and expectations of its customers in an efficient and effective manner. This involves ensuring the availability of products or services at the right time and place, meeting quality standards and delivering a satisfactory customer experience.

What are the risks and benefits of a high level of service?

A high level of service increases customer satisfaction, improves customer loyalty, and strengthens brand reputation. However, it also entails risks, mainly linked to the need to hold larger stock. Some of these risks relate to higher operating costs due to larger inventories and the risk of obsolescence from accumulating too much stock.

What are the risks and benefits of a low level of service?

A low level of service in the supply chain can reduce operating costs by minimising inventories and simplifying logistics. However, this carries significant risks, such as customer dissatisfaction due to unavailability of products or services, which can lead to customer churn and damaged brand reputation. In addition, a low level of service can limit business growth and competitiveness vis-à-vis companies with a better level of service.

What is the relationship between service level and safety stock?

A higher service level generally requires a larger safety stock to ensure products are available when customers need them, especially during peaks in demand or times of uncertainty in the supply chain. On the other hand, a lower service level may allow a reduction in safety stock, but at the cost of increasing the risk of stockouts and potentially affecting customer satisfaction.